Products containing cannabidiol (CBD) are gaining popularity. Monitoring important measurement data is the basis for the successful production of raw material and finished products. The market for medical cannabis is growing and increased number of companies are getting Good Manufacturing Practice (GMP) certification.

There are three categories for medical cannabis:

1. Medicines: cannabis is an active substance.

2. Preparations: the plant is subjected to certain treatments, like extracts, resins, and oils.

3. Substances: the plant is not subjected to any treatments, like dried flowers.

The cultivation and primary processes of medicinal cannabis leads to an end product (dried whole flowers) that is an active pharmaceutical ingredient (API).

Two regulations come into play during the cultivation and primary processing of medicinal cannabis:

1. Good Agricultural and Collection Practice (GACP) for the cultivation

a. Propagation

b. Vegetative phase

c. Flowering

d. Harvest

2. Good Manufacturing Practice (GMP) for the processing and manufacturing

a. Drying

b. Warehouse storage

c. Trimming

d. Extraction and encapsulation

e. Testing

f. Packaging

During the testing phase within the laboratories, Good Laboratory Practice (GLP) regulations are subjected to medicinal cannabis, where the environment, fridges, freezers, incubators and other such equipment is monitored. The most important monitoring parameter is temperature, which is essential to guarantee the product quality and establish stability data.

Once the final product is packed, then Good Distribution Practice (GDP) regulations come into play for the transport of medicinal cannabis. As with all pharmaceutical products, data integrity, transparency and traceability are required during all steps of the supply chain. All the regulations can be fulfilled with the Rotronic real-time monitoring solutions.

What is GACP

GACP is a regulation setup to ensure consumer safety by establishing appropriate quality standards for medicinal plants and herbal substances. These quality standards include:

- Hygenic production (reduce the microbiological load).

- Handled with care (not adversely affected during collection, cultivation, processing and storage).

- Recommendations to reduce contamination.

The quality management system, should ensure that thresholds are maintained for:

- Mycotoxins,

- Microbial contaminants

- Heavy metals

- Pesticide residuals

- Foreign matter.

During the cultivating phase of medical cannabis, there are 10 cardinal parameters which need monitoring. Five of them are environmental, so the core competence of our realtime-monitoring system:

- CO2 content

- Relative humidity

- Daily light integral (DLI)

- Temperature

- Airflow

In order to improve the growth yield, control and monitoring of these parameters is crucial.

To become GMP certified for medicinal cannabis processing, among others, a regularly calibrated and validated continuous environmental monitoring system is required as of the drying stages.

Water activity (aw) is a measure of the available water that can be utilized for microbiological growth. Rotronic aw devices are the perfect solution for on-site water activity measurements to confirm product stability and indicate shelf life. Water activity can also be measured to carry out batch release processes of the dried product or oil. Most Cannabis is dried and cured to a final water activity level of aw 0.30 – 0.60.

Additional areas that we help serve and measurement data we monitor in the cannabis industry:

- Differential pressure

- Light

- O2

- Particel counting

- pH

- Soil moisture

- Water activity

Within

- Growing

- Indoor air quality

- Fridges and Freezers

- Laboratory monitoring

- Vault and door interlock

Advantages of digital systems

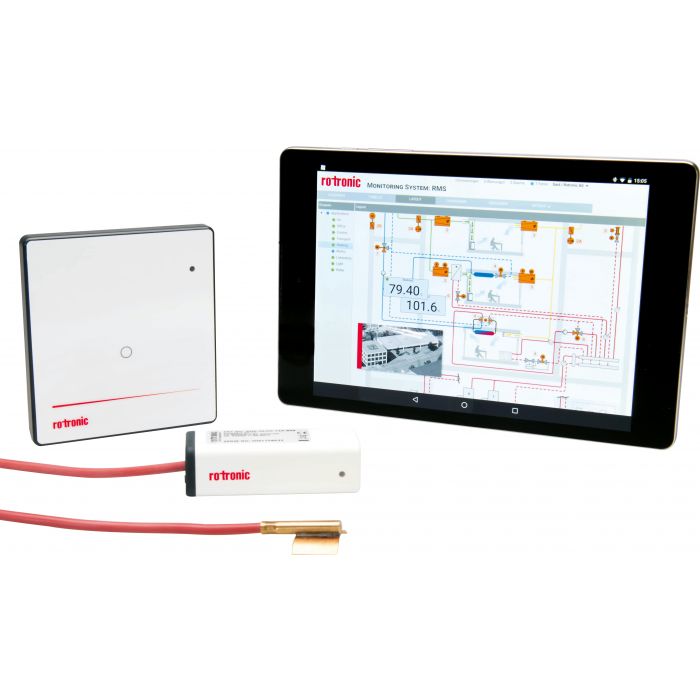

The Rotronic digital sensors communicate to data loggers (wired or wireless) and all communication to the server and database is done digitally as such there is no loss in accuracy during data transmission. This means, unlike analog sensors, no loop check is required during device installation and qualification/validation.

A major advantage of using digital sensors within an Environment Monitoring System (EMS) is the possibility to use the additional data and reduce the amount of downtime, this is especially valid during the calibration period or service periods.

Read more in our blog

Lean validation

With a Site Acceptance Test (SAT) is the documented verification that the system meets the desired and required specifications. Rotronic carry out the SAT according to written and pre-approved specifications, normally written within the Configuration Specifications (CS) and within the Functional Requirements Specifications (FRS).

The objective of the document is to document the checking, testing or other verification to demonstrate that the system meets the desired and required specifications.

During the SAT, the system is evaluated at the customer’s site. Where appropriate and justified, documentation review and some tests could be performed during the SAT or other stages without the need to repeat on site during the IQ/OQ.

Product security

It is important to note that product security is critical, as for example in Switzerland the handling of non-medicinal cannabis continues to be generally prohibited and losing finished products can result in losing the GMP certification. The Rotronic Monitoring System also offers vault and door monitoring as well as triggered video monitoring.

Was this interesting for you or would you like to have more information?

Subscribe to Newsletter